The Role of Technology in Production

In today’s fast-paced world, technology is an indispensable component of almost every aspect of production. From the evolution of manufacturing technology throughout history to the latest technological advancements, the production landscape has been continuously reshaped. This blog delves into the transformative journey of technology in manufacturing, highlighting key technologies, examining their impact on production processes, and exploring their role in sustainable practices. Additionally, we address challenges faced by the industry, learn from real-world examples of success, and ponder future trends that are set to revolutionize production. Join us as we navigate the intricate interplay between technology and production, unraveling how these advancements influence efficiency, innovation, and sustainability.

1. Historical Perspective: Evolution of Manufacturing Technology

The evolution of manufacturing technology is a testament to human ingenuity and the drive for efficiency. In the early days of production, manual labor was the backbone of manufacturing. Craftsmanship ruled the day with each product being a unique creation, requiring time and skilled hands. The Industrial Revolution brought with it a wave of change, introducing machinery that would transform the industry forever.

During the Industrial Revolution, inventions such as the steam engine and mechanized looms introduced automation to manufacturing processes. This era marked a shift from artisanal work to mass production, leading to significant economic and social changes. The 20th century saw further advancements with the introduction of assembly lines and electrical power, giving way to the rapid industrial growth seen in the post-World War II era.

In recent decades, the digital revolution has ushered in new possibilities. Computer-aided design (CAD) and computer-aided manufacturing (CAM) have revolutionized precision and efficiency in production. As we moved into the 21st century, more sophisticated technologies like artificial intelligence (AI) and the Internet of Things (IoT) began to redefine what was possible in the manufacturing space.

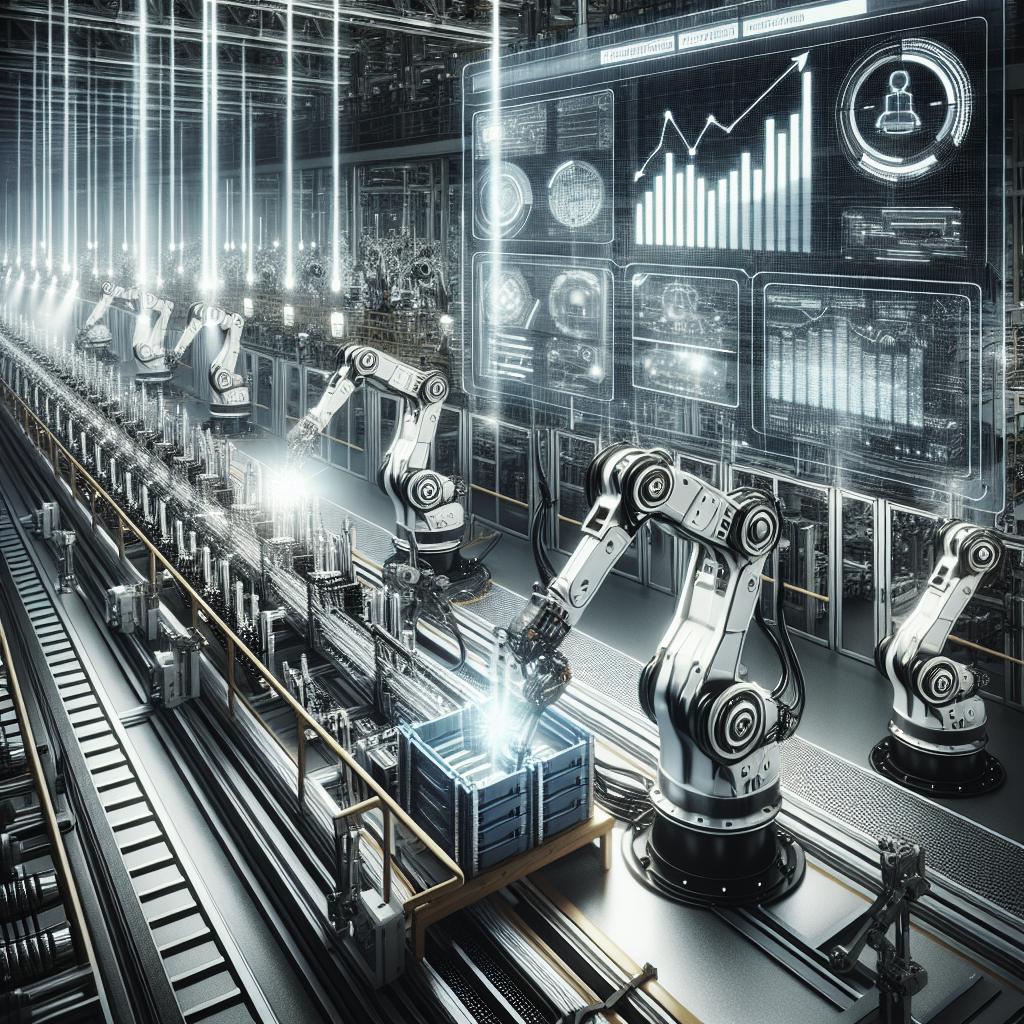

2. Key Technologies Shaping the Manufacturing Industry

In the current manufacturing landscape, several key technologies are driving transformation. Robotics stands at the forefront, with robots taking on roles that are hazardous, repetitive, or require precision beyond human capabilities. These machines increase production speed and efficiency while enhancing safety and quality control.

Another critical technology is the Internet of Things (IoT). By embedding sensors in equipment, manufacturers can collect real-time data to monitor production systems. This connectivity allows for predictive maintenance, reducing downtime and improving overall operational efficiency. Similarly, big data analytics provides the ability to process and analyze vast amounts of information, enabling better decision-making and strategic planning.

Lastly, additive manufacturing or 3D printing is revolutionizing the industry by allowing for rapid prototyping and on-demand production of complex parts. This technology offers flexibility in manufacturing, reducing waste and allowing companies to innovate with previously impossible designs.

3. The Impact of Technology on Manufacturing Processes

Technology has profoundly impacted how manufacturing processes are conducted, allowing for greater efficiency, precision, and versatility. Automation has diminished the reliance on human labor for repetitive tasks, freeing up skilled labor for more strategic roles. This has resulted in faster production times and reduced error rates.

Furthermore, digital tools like CAD and CAM have streamlined design and prototype phases, allowing manufacturers to bring products to market more quickly. These technologies have also facilitated advanced customization, enabling manufacturers to cater to specific consumer needs with greater precision.

The integration of IoT in production lines has elevated process monitoring and control. By harnessing real-time data, manufacturers can optimize production schedules, manage energy usage, and ensure that equipment operates at peak efficiency. The result is a more agile, responsive manufacturing environment capable of rapid adaptation to market demands.

4. The Role of Technology in Sustainable Manufacturing

Sustainability in manufacturing is becoming increasingly vital, and technology plays a crucial role in achieving eco-friendly goals. Automation and precision engineering reduce material waste by optimizing production processes, leading to more sustainable operations.

Additionally, technologies such as IoT and big data analytics help manufacturers track and improve their energy efficiency. By analyzing energy consumption patterns, companies can implement changes that reduce their carbon footprint, thus adhering to environmental regulations and promoting a greener economy.

3D printing offers another avenue for sustainable manufacturing by enabling localized production, which can significantly reduce transportation emissions. The on-demand nature of 3D printing also means less inventory waste, contributing to a more sustainable production model.

5. Challenges and Considerations

While the role of technology in production offers significant benefits, it also presents challenges. Implementing new technology requires substantial investment, both financially and in terms of time for training and integration. Small and medium enterprises may find these initial costs prohibitive unless adequately supported.

Cybersecurity is another pressing consideration. As manufacturing systems become more interconnected through IoT and other technologies, they are increasingly vulnerable to cyber threats. Companies must invest in robust security measures to protect sensitive data and ensure the continuity of their operations.

Moreover, the shift towards automation raises concerns about job displacement. While new jobs are created to support these technologies, there is a need for retraining and upskilling workers to ensure they remain relevant in the ever-evolving manufacturing landscape.

6. Real-World Use Cases and Success Stories

Several real-world examples demonstrate the successful integration of technology in manufacturing. For instance, Siemens has embraced digital twin technology to create virtual replicas of its products. This innovation allows for extensive testing and optimization before actual production, significantly reducing time-to-market and production costs.

Similarly, automotive giant Tesla has revolutionized car manufacturing by employing cutting-edge robotics and AI in its production lines. This approach has enabled Tesla to rapidly scale production while maintaining high-quality standards, setting a new benchmark for the automotive industry.

Another success story is General Electric’s implementation of IoT and analytics in their industrial operations. By embedding sensors and leveraging real-time data, GE has optimized maintenance schedules, resulting in significant reductions in downtime and operational costs.

7. The Future Outlook: Emerging Trends and Innovations

As we look to the future, several emerging trends and innovations are expected to shape the manufacturing industry. Artificial intelligence and machine learning will continue to drive efficiency and innovation, enabling smarter, more autonomous production systems.

Another trend is the increased adoption of cloud computing, providing manufacturers with enhanced computing power and data storage capabilities. This allows for seamless collaboration and more agile responses to market changes.

Moreover, the emphasis on sustainability will lead to further advancements in green technologies. Renewable energy integration, as well as the development of biodegradable materials, will become more prevalent, moving the industry towards a more sustainable future.

8. Final Thoughts

In conclusion, the role of technology in production is both transformative and multifaceted. As manufacturing continues to evolve, it is clear that technology will remain a pivotal driver of innovation, efficiency, and sustainability. While there are challenges to overcome, the integration of these technologies promises a brighter, more responsive future for the manufacturing industry.

| Section | Summary |

|---|---|

| Historical Perspective | Explores the transition from manual craftsmanship to modern automated production. |

| Key Technologies | Discusses robotics, IoT, and 3D printing as transformative technologies. |

| Impact on Processes | Details how technology enhances production efficiency and customization. |

| Sustainable Manufacturing | Highlights technology’s role in reducing waste and energy consumption. |

| Challenges and Considerations | Addresses financial, cybersecurity, and workforce challenges. |

| Use Cases and Success Stories | Features examples from Siemens, Tesla, and GE showcasing successful technology integration. |

| Future Outlook | Highlights emerging trends like AI, cloud computing, and sustainability advancements. |